Waste Management

Download this Issue Brief (PDF)

Importance to Elanco and our Stakeholders

We understand our business operations produce byproducts we manage through reuse, recycling and conventional waste streams. Elanco strives to assess the many impacts of operational waste, in the pursuit of improving effects to human and public health, land and water, and to global warming.

We recognize packaging waste as a significant contributor to waste streams globally. Elanco’s sustainable packaging and logistics initiatives help reduce greenhouse gas (GHG) emissions and waste, while providing opportunities to develop value chain partnerships that can enhance our positive impact and drive industry-wide change.

Our Action

In addition to general office waste, our manufacturing processes and the raw materials we purchase from suppliers result in various solid and liquid waste. Our Health, Safety, and Environment (HSE) organization maintains standard operating procedures (SOPs) detailing appropriate processes for management and disposal methods of both nonhazardous and hazardous waste material, which may include such things as packaging materials from purchased raw materials or byproducts of our manufacturing processes.

Our Global Environmental Standard outlines the expectation that employees dispose of hazardous and non-hazardous waste appropriately, while seeking to reduce the overall amount of waste generated by our operations. For example, the standard indicates our preference to dispose of expired or unsold medicines via a destructive disposal process (such as incineration) rather than sending to a landfill. We also regularly donate unused product in lieu of disposal – to support non-profit animal shelters, clinics and other organizations in need around the world, while reducing our waste footprint. We regularly review the standard to ensure it provides the best direction for employees as they manage our operational waste.

Elanco sites advance numerous initiatives to reduce our waste footprint and increase recycling or reuse:

- Reuse in our wastewater: Waste from our fermentation process is applied to farm land as fertilizer due to its beneficial nutrient value. Also, at our Clinton, Indiana manufacturing site, improved maintenance practices and tighter operational controls have reduced Elanco's effluent phosphorous content - which allows for more than 90 million gallons of water a year to be reused in cooling towers.

- Recycling in our communities: In Brazil, we collaborate with Eureciclo, an organization focused on packaging recovery, to help ensure approximately 20% of our packaging materials in Brazil will be recycled. These efforts keep an average of over 300 tons of materials from landfill annually and will contribute to further development of recycling infrastructure and awareness in Brazil.

- Reuse in our logistics: Our manufacturing site in Kiel, Germany receives thousands of shipping pallets with inbound deliveries each year and reuses the pallets to package outbound freight.

- Recycling in our manufacturing sites: Our manufacturing site in Clinton, Indiana operates a recycling initiative for plastic buckets, metal buckets and corrugated boxes that result from packaging of our raw materials used in the manufacturing process. The initiative provides a clean, high-quality source of recycled polyethylene and polypropylene for the growing recycled plastics market and diverts tons of metal from landfills. Additionally, the Clinton facility makes a 40-yard dumpster available to the local community to support recycling – as the local authority does not yet offer doorstep recycling service.

- Reducing materials use: Across several product lines, we changed from solvent-to water-based inkjet printing – reducing lacquer use, volatile organic compound (VOC) air emissions and inkjet cartridge waste.

- Minimizing Electronic Waste: In 2023, Elanco partnered with "Framework," a company focused on building modular laptops with enhanced end-user repairability. This new approach has helped reduce e-waste and the expense of replacing damaged machines with entirely new units. Based on the results, Elanco hopes to roll out the program in additional areas.

Returned Product

In the U.S., our commercial policies allow for product return if certain criteria are met, as outlined in our Terms and Conditions of Sale and in our commercial contracts. When returned product is received at designated facilities, either at third-party partners or by Elanco directly, SOPs for disposal and waste management are applied.

In rare instances, we may evaluate a product for reintegration into the supply chain. In such circumstances, our U.S. Affiliate Quality (USAQ) team would apply SOPs to assess the product’s suitability for reintegration into the supply chain. For markets outside of the U.S., our affiliates have local commercial policies which define return procedures with respect to local regulations.

Sustainable Packaging

Well-designed packaging is essential to facilitate reliable transport from manufacturing site to end user, protect product quality and efficacy, help ensure safe handling and inform users about product ingredients and appropriate use. At the same time, an unfocused approach to packaging can over-consume natural resources, create excess material or handling costs and result in additional waste to landfill. Elanco is committed to a sustainable packaging strategy that ensures product integrity while minimizing negative environmental impacts, as outlined in our Sustainable Packaging Guideline.

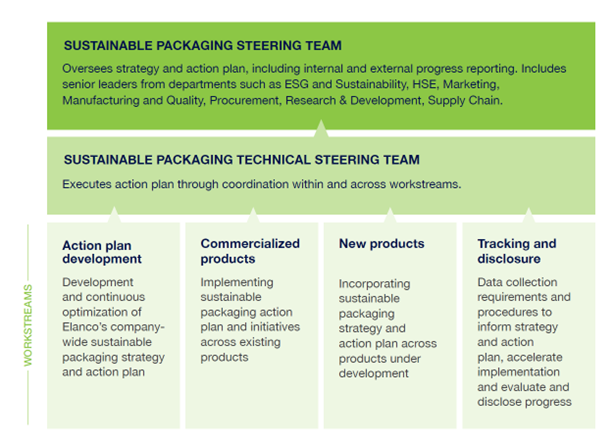

Our global, cross-functional sustainable packaging steering team helps to accelerate our efforts, formalize the global sustainable packaging guideline and action plan, and embed our strategy into product development, marketing and logistics processes and responsibilities across the company.

Elanco applies a 5Rs approach to sustainable packaging – focusing on opportunities across primary, secondary and tertiary packaging:

- Reduce

- Reuse

- Recycle

- Replace

- Renew

Sustainable packaging is an important way Elanco can support global progress toward a circular economy. Our efforts include increasing the use of environmentally sustainable packaging materials and removing elements in our packaging and logistics processes that create unnecessary waste, emissions or spending. In addition to minimizing our environmental footprint and unnecessary costs, we seek to align with increasing interest in sustainable packaging from customers, regulators, investors and other stakeholders.

Factors informing our strategy and action plan include:

- Materials use: We continue to assess our packaging footprint, to inform future specific reduction targets.

- Scope 3 GHG emissions: Our work to understand and positively impact Elanco’s Scope 3 GHG emissions includes understanding how sustainable packaging and logistics initiatives can reduce our environmental footprint.

- Regulatory requirements: Our strategy will address the increasing scope and scale of packaging-related regulation in the jurisdictions where we operate. Proposed changes to primary packaging may be slowed by regulatory agency approval requirements for these changes.

- Customer expectations: Sustainable packaging is increasingly important to our customers and our ongoing customer engagement activities inform our strategy.

Sustainable packaging innovations

- Simplifying tertiary packaging: We eliminated corrugated pallet caps for all Interceptor®Plus packaging in our U.S. and Canada markets – keeping approximately 6 tons of waste from landfills annually.

- Streamlining shipping: In Latin America, we eliminated a double layer of boxes used for shipping Asuntol®Soap in Colombia and Ecuador – saving approximately 30,000 boxes per year.

- Reducing plastic consumption: We changed stretch film at our Clinton, Indiana manufacturing site to a high-performance, thinner option – reducing plastic consumption by more than 20 tons per year

- Slimmer primary packaging: To reduce packaging inputs from one of our leading products, we streamlined the design of our Seresto packaging tin, resulting in annual savings of more than 88 tons of tin, more than 4.4 tons of lacquer and more than 8,600 square feet of foil.

- E-Commerce optimization: Recognizing that e-commerce partners don’t require the cardboard displays in-person retailers find valuable, we customized shipping of Seresto for these vendors –eliminating the use of approximately 538,000 square feet of corrugated cardboard annually.

- Compostable packaging: For selected products, we’ve implemented a new packaging cushion, “green cell foam” – a protective bulk packing layer that is made from corn and is 100% compostable.

Also, for selected products, our “cold ship” packaging is no longer made from expanded polystyrene foam (EPS). Elanco worked with packaging suppliers to help develop a non-heat-conductive natural starch foam which traps air in a denser manner than legacy solutions, to provide effective cold protection. Along with protective cardboard stiffening panels, the cold insulating package is customizable to any size needed for shipping – unlike die-constrained EPS. Once our materials are packaged, instead of frozen CO2 (dry ice), we will use cooling gel packs composed of a nitrogen-based liquid that when thawed can be recycled as fertilizer. This innovative cold packaging format is certified to provide protection for two-day shipments. The total carbon footprint savings and sustainability benefits of this novel approach have not yet been calculated, but compared to EPS and dry ice, we expect the benefits to be considerable.

We are committed to continuing to collaborate with our suppliers, manufacturing sites and packaging experts to make our packaging processes even more sustainable in the future.

Hazardous Waste Management

Elanco follows strict hazardous waste management protocols to ensure safe handling and disposal of hazardous materials. We employ a comprehensive waste management system which includes waste characterization, segregation, storage, transport and disposal. Hazardous materials, such as chemicals and solvents, are handled by trained personnel.

All hazardous waste management includes proper labeling, containment and storage in designated areas with proper spill protection. All regulatory hazardous material practices are followed for any waste generation, handling, transport and disposal.

Elanco is committed to continuously improving its hazardous waste management practices to minimize impact on the environment and local communities.

Metrics and Targets

Please view our ESG Key Performance Indicators

Governance and Risk Management.

Our Board and executive management team are actively engaged in Elanco’s activities and approach to addressing climate-related risks and opportunities. The Corporate Governance Committee provides oversight and guidance for our overall ESG and sustainability program, including our strategy, programs and policies related to climate change and operational sustainability. These include emissions and waste reduction efforts, consumption of energy and water, and investments in renewable energy – such as our commitment to source renewable electricity equivalent to 100% of our electricity use by 2030. Additionally, the Audit Committee reviews policies and practices related to environmental protection, monitors compliance and reports or makes recommendations to the full Board, as appropriate.

Our Head of Investor Relations and ESG oversees internal management of Elanco’s climate-related strategy, programs, goals and disclosures – with further oversight from the Elanco Healthy Purpose Steering Committee. Our Health, Safety and Environment team – part of our manufacturing and quality business unit and led by our Senior Director of Global HSE – has operational responsibility for the resilience of our operations, including energy and water use, as well as waste and emissions management. HSE receives oversight from the global HSE Steering Committee, a cross-functional group that includes representatives such as our Executive Vice President of Human Resources, Communications and Administration; our Executive Vice President of Innovation and Regulatory Affairs; our Executive Vice President of

Manufacturing and Quality; our Executive Vice President, General Counsel and Corporate Secretary; and our Head of Investor Relations and ESG.

Our global sustainable packaging activities are managed by our Global Senior Packaging Engineering Advisor to direct our global packaging initiatives. In addition, all business areas, including Manufacturing and Quality, Research and Development, affiliate locations and general administrative offices, are required to operate with an HSE management system that adheres to the requirements of the Elanco HSE Policy and associated standards. The basic elements of the HSE Management System Standard align with internationally recognized management systems such as ISO45001 (Occupational Health and Safety Management Systems), ISO14001 (Environmental Management Systems), American Chemistry Council’s Responsible Care Management System and the Occupational Safety and Health Administration Voluntary Protection Program.

Annual performance measures for our Senior Director of Global HSE, members of our global ESG and sustainability team and other senior leaders across our business include climate-related objectives. These may include progress toward our renewable electricity goal or other environmental impact reduction initiatives, as well as accurate and transparent disclosure of our environmental metrics and programs.

Sustainable Packaging Governance

We continue to mature our global, cross-functional sustainable packaging steering team to accelerate our efforts, formalize a global sustainable packaging guideline and action plan, and embed our strategy into product development, marketing and logistics processes and responsibilities across the company.

The content of this brief is informed by global ESG disclosure standards and frameworks.

Updated July 2024

Sobre a Elanco

Saiba por que somos um fornecedor líder em soluções inovadoras que protegem e melhoram a saúde animal.

Saiba Mais Elanco and the diagonal bar logo are trademarks of Elanco or its affiliates. © 2022 Elanco.